Supply chain planning has always been hard, and it’s getting harder. Global conflicts, unforeseen events, and other uncontrollable factors often cause disruptions in the supply chain, making it challenging – and time-consuming – for brands to stay agile and make good decisions.

However, the rise of machine learning (or “ML”) technology presents new opportunities for supply chain managers. These new programs are already making it easier for businesses to make accurate predictions and inform their supply chain planning, and will only get more sophisticated over time.

In this post, we’ll dive deeper into the use of machine learning in supply chain logistics, explore how machine learning can benefit supply chains, and share tips for how it can improve your supply chain management.

What is machine learning in supply chain logistics?

Machine learning is a type of artificial intelligence (AI) technology that uses data and algorithms to identify patterns and make informed decisions.

In supply chain logistics, machine learning technology collects large amounts of data from across various supply chain processes. It then analyses this data to make smart predictions and suggestions for supply chain optimisation.

Machine learning programs can be used to gather advanced supply chain analytics so you can easily get actionable insights on performance. Machine learning also enables supply chain automation to a significant extent, allowing you to automate things like demand forecasting and route optimisation. As such, machine learning is vital for enhancing supply chain efficiency, saving time, and improving your overall performance.

The evolution of machine learning in logistics

The logistics industry once largely relied on paper-based systems that involved a lot of manual tracking and required implicit, learned knowledge to make effective decisions. When the first enterprise resource planning (ERP) systems were introduced in the late 1980s, they helped streamline and simplify supply chain logistics management.

These ERP systems helped to centralise supply chain processes into a single software. However, they weren’t equipped to process vast amounts of data in real time or make decisions that considered all the intricacies of supply chain dynamics. This often led to incomplete insights and inaccurate predictions, which resulted in sub-optimal supply chain decisions.

Flash-forward to present day, and businesses can now access technology that’s capable of collecting and analising vast amounts of data in real time from across various supply chain processes. The development of advanced machine learning algorithms that perform predictive analytics now help brands make real-time decisions using this data, making it possible for ecommerce businesses to improve supply chain efficiency and oversee their supply chain operations with minimal human oversight.

Modern supply chain technology also leverages machine learning to help automate various activities. This includes IoT devices and robotics that leverage machine learning to automate tasks like warehouse monitoring, picking, packing, and inventory tracking.

Key benefits of machine learning for supply chains

With its ability to analyse massive data sets in real time and speed up decision-making, machine learning can be highly beneficial for supply chains. Let’s break down some of these key machine learning benefits that are applicable to supply chain operations.

Predictive accuracy

Machine learning algorithms are capable of analising huge volumes of historical data as well as current order data to identify demand patterns. You can use this capability to get accurate predictions about future demand. This streamlines your demand planning efforts, enabling you to plan for production and procurement so as to avoid stockouts and overstocking.

With better predictive accuracy, you can optimise your supply chain planning to effectively meet customer demand. You’ll be able to plan ahead based on predicted customer demand, transit times, and production lead times.

Decision-making

With their ability to perform real-time data analysis, ML algorithms help take the guesswork out of major supply chain decisions and facilitate better decision-making. Because machine learning algorithms are capable of constantly learning based on new data, ensuring to provide the most updated and relevant insights, businesses can use them to make data-driven decisions on which suppliers to use, how much stock to order and when, how to arrange and distribute inventory, which picking strategies to use, and more. Machine learning can even inform decisions about optimal delivery routes so businesses can improve delivery management and enhance customer satisfaction.

Cost efficiency

Machine learning offers a number of benefits to improve cost savings within the supply chain. Some applications of ML algorithms to save money include:

- Using real-time traffic data to recommend the most efficient delivery routes so you can reduce fuel costs.

- Factoring in current weather conditions, ensuring there’s minimal delays on shipments and avoiding costly reshipments and disgruntled customers.

- Accurately predict demand to help businesses maintain optimal stock levels and reduce carrying costs.

- Reducing inefficiencies in supply chain processes to save time and reduce spending throughout the entire supply chain.

Scalability

One of the most appealing characteristics of machine learning technology is its adaptive and scalable nature. Its applications are highly diverse, allowing you to leverage it across the end-to-end supply chain. Whether this involves demand planning at the procurement stage or route planning for last-mile delivery, you can adapt the technology according to your unique needs.

Additionally, machine learning tools are capable of scaling with your business, even if this involves dealing with more data. In fact, the more data it processes, the more it will learn, helping you achieve even better accuracy with your forecasting and decision-making.

“When comparing ShipBob’s technical capabilities to those of many other fulfilment competitors, it’s crucial to investigate further to grasp the underdeveloped state of the technology infrastructure at several larger, well-known fulfilment companies. Some of these companies are just now beginning to construct a technical framework capable of accommodating the scalability of their operations and addressing the evolving needs of their merchants. However, most are still holding onto unscalable legacy systems, which are filled with makeshift solutions to address issues for their larger clients. Improving these systems is painstakingly slow and impedes growth at fast-growing companies.

Comparing ShipBob’s platform to other fulfilment providers, it’s challenging to find a match for its extensive technical capabilities. ShipBob’s architecture is exceptionally robust, underpinning a comprehensive technology stack that seamlessly scales to accommodate businesses transitioning from small to mid-market and beyond.”

Ali Shahid, COO of Our Place

Practical applications of machine learning in supply chain management

As machine learning’s popularity has grown, ecommerce businesses have found more and more ways to leverage it to their advantage. Here are just some of the ways that brands are using machine learning to improve their supply chain management.

Predictive demand forecasting

Supply chain professionals can use machine learning algorithms to identify patterns in demand and make accurate demand forecasts. Machine learning tools can analyse historical sales data and demand trends and combine them with current market trends to forecast demand.

These forecasts can then be used for data-driven demand planning. Combined with real-time data on inventory levels, you can get an accurate understanding of your inventory needs using these demand predictions. This optimises the inventory planning process by ensuring that you’re stocking up enough inventory to meet customer demand without keeping excess inventory.

Route optimisation and load balancing

One of the most popular uses of machine learning in supply chain management is in delivery route planning. ML algorithms can factor in various external factors like traffic and weather conditions to recommend optimal delivery routes. This can help you find the fastest, most efficient stop sequence for drivers so as to reduce delivery times and avoid delays.

In addition to on-time delivery, you can also enjoy some cost benefits through reduced fuel spendings. This also supports your sustainability efforts, as reduced travel time translates to a lower carbon footprint.

Additionally, you can use machine learning to predict package volumes and optimise load distribution. This helps you reduce the risk of overloading delivery vehicles as you can strategically balance loads between different drivers.

Automated inventory management

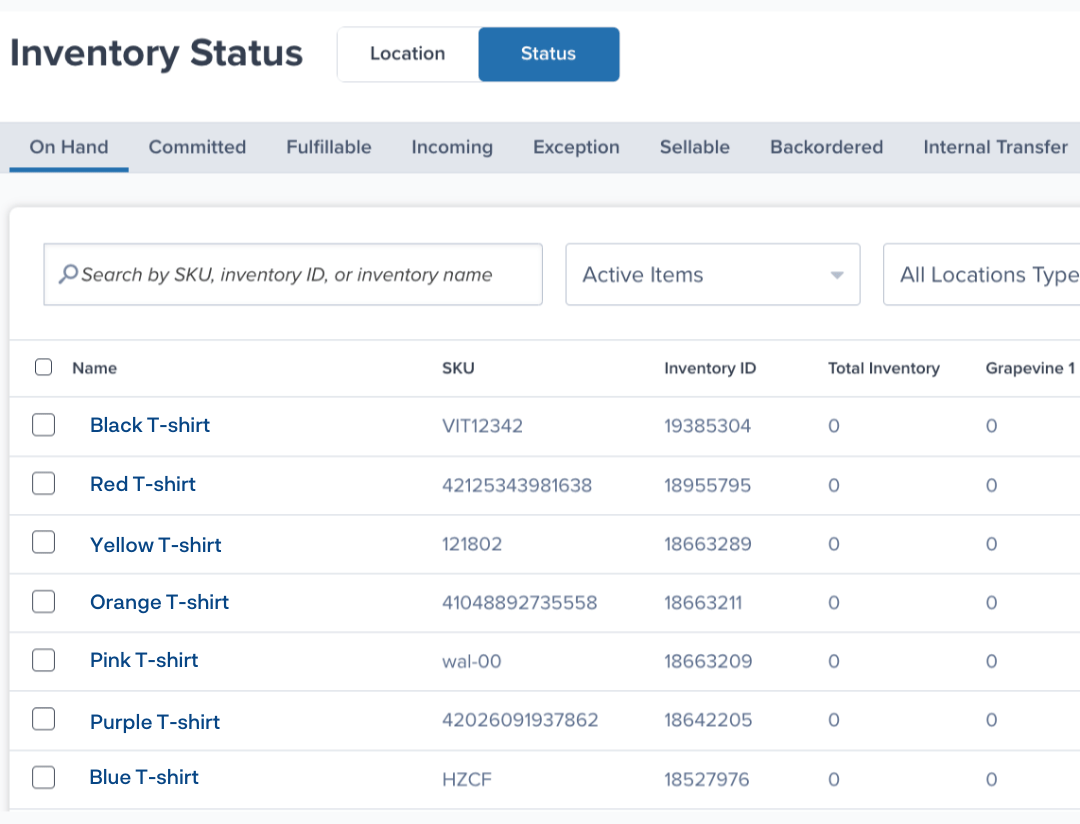

Machine learning also has several applications in inventory management. It can be used to track real-time inventory levels from across various warehouses and supply chain processes. Inventory levels are automatically updated in the system based on real-time order data and fulfilment activity, which helps to automate the inventory tracking process, simplifying inventory management.

You can use this inventory performance data to automatically identify your slow-selling items and fast-moving SKUs. This will not only inform your replenishment strategy but also help you understand which items to focus on and which ones you may want to discontinue.

Some inventory management systems can even use ML technology to determine reorder points based on historical sales data and replenishment patterns. It then sends reorder notifications so you’re automatically alerted when it’s time to replenish your stock. That way, you minimise the risk of stockouts because you’re reordering inventory at the right time.

“Trying to figure out how much of what inventory to send where could be wildly complex for our supply chain managers – but since ShipBob automatically tracks our order and shipping data for us, that data basically tells us our optimal inventory distribution. We also get automatic reminders notifying us well before inventory levels are getting depleted, so we don’t have to constantly be checking our stock levels.”

Tyler McCann, Co-Founder of Taste Salud

Workflow automation in fulfilment centres

Machine learning algorithms can also be used to facilitate supply chain automation across warehouses and fulfilment centres. Warehouse management systems equipped with ML technology can:

- Recommend optimal picking strategies based on your unique business needs.

- Calculate the most efficient picking routes so your picking staff doesn’t have to travel back and forth between different locations, reducing travel times.

- Generate picking lists based on these calculations, helping to automate task allocation.

- Calculate ideal package dimensions for each order during packing.

- Make packing recommendations to speed up the packing process to a significant extent, so packing staff will no longer have to guess or rely on implicit knowledge to determine how to pack orders. This speeds up packing, saves you money on packing costs (since you won’t be wasting money on excess packing materials), and helps reduce shipping costs by using the ideal box size for each package and reducing package dimensions.

- Streamline courier selection by automatically calculating the shipping costs with each courier, allowing you to compare rates between multiple couriers and choose the most cost-effective solution without sacrificing delivery speed.

Key machine learning technologies in supply chains

There are several machine learning technologies that can be used for various supply chain functions. Let’s explore some of the key technologies that you can find in most supply chains.

Predictive analytics in supply chain management

Predictive analytics is one of the most common machine learning technologies used in the supply chain management process. It analyses large datasets on historical sales performance and demand patterns over time. The algorithm then makes intelligent forecasts on how customer demand might change in the future.

This allows supply chain professionals to get a better understanding of future inventory needs and plan their procurement accordingly, so it plays a vital role in inventory optimisation, ensuring that you’re maintaining sufficient stock to keep up with customer demand. As a result, you can also avoid common inventory problems such as stockouts, overstocking, and backorders.

Similarly, machine learning can also analyse demand patterns across different regions. This is used to provide predictive insights about how demand might change based on location. It can then recommend optimal inventory distribution strategies to effectively meet customer demand across all locations. You can allocate inventory strategically to ensure that certain warehouses carry more inventory while other locations hold less stock based on region-wise forecasts.

Additionally, machine learning can collect and analyse incident data from various sources. This allows you to identify possible supply chain risks before they turn into major problems. As a result, you can proactively mitigate risk by forecasting where they could happen and prevent them from disrupting your supply chain operations.

Robotics and automation in fulfilment centres

Automation is another aspect in which machine learning technology can be applied in the supply chain. It can be integrated with robotics to facilitate warehouse automation and streamline various tasks.

Warehouse robots rely on machine learning to aid navigation and coordination. This allows them to perform various tasks and move seamlessly within the warehouse to help with various ecommerce fulfilment processes. For instance, robotic arms can be programmed to aid human workers with retrieving packages.

Additionally, warehouse management tools enhanced with computer vision are also used to identify packages and scan barcodes. This helps to automate and streamline inventory tracking, ensuring that inventory records are updated in real-time along with each transaction.

IoT devices also make use of machine learning for real-time warehouse monitoring. These can collect real-time inventory data based on product movement and various warehouse activities. This not only helps to anticipate inventory needs and predict demand, but it’s also highly effective for detecting anomalies. Any unusual patterns, delays, or errors are instantly flagged, so you can immediately identify the source and identify a solution.

These devices can also automatically detect temperature fluctuations, leakages, and other issues that could affect storage conditions. That way, you can keep a close eye on your inventory and ensure that it’s stored safely. This level of automation is particularly useful when dealing with items that need to be stored under specific conditions.

How ShipBob uses machine learning to drive ecommerce success

As an expert supply chain platform, ShipBob leverages machine learning throughout our warehouse management system (WMS) and fulfilment operations to improve operational efficiency throughout the supply chain, reduce operational costs, boost accuracy, and ultimately facilitate ecommerce success.

Real-time data for demand forecasting

ShipBob’s cloud-based software collects vast amounts of inventory and sales data across your sales channels and fulfilment centres, including up-to-date information on inventory levels. Our software combines this real-time inventory data with historical sales and inventory performance data to help you plan your inventory procurement more effortlessly with minimal manual calculation, and accurately forecast demand.

“One of our main priorities was finding a reliable partner that could store all of our inventory and provide tools that would help us manage it. We rely heavily on ShipBob for inventory tracking and forecasting and that’s been a key part of our partnership. Our area of expertise is not logistics or inventory management, so we lean on ShipBob a lot for that. We’ve learned so much about this industry since working with ShipBob, as they are true supply chain experts, which has been good for everyone on our team.”

Callie Tivnan, E-commerce Manager, and Christina Williams, Customer Success Manager at Barefaced

Smart inventory allocation and distribution

ShipBob’s Inventory Placement Program lets you intelligently distribute your inventory across different fulfilment centres. The program uses a proprietary machine learning algorithm to analyse how your inventory has moved and turned over across different locations over time. It then makes intelligent predictions about how much inventory you’ll need at different fulfilment centres to meet demand in the surrounding area most effectively.

Using this program, you can store your inventory closer to your customers and ensure that they’re shipped out from the most convenient locations. As such, you can save on shipping costs while improving delivery speeds.

“When we first got started, we checked how ShipBob’s Inventory Placement Program was distributing our inventory based on the models we created when we did distribution in-house – they were on point. ShipBob’s machine learning data works. They took a container with 1,000 SKUs and knew exactly which inventory needed to go to which facilities. On top of time savings, we were able to realize cost savings because we didn’t have to make any inventory transfers. We send our inventory to ShipBob once, they receive it, and they distribute it across their US network. We’re saving thousands of dollars each month by using IPP.”

Cesar Contreras, Head of Supply Chain of Wholesome Goods

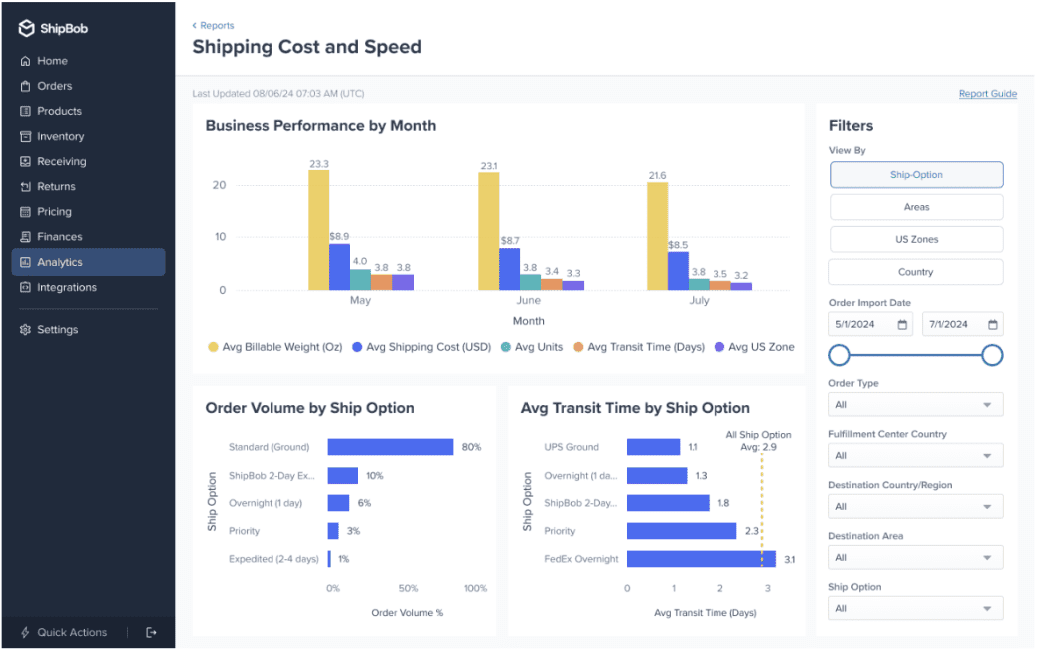

Data-driven analytics for optimisation insights

ShipBob’s powerful analytics dashboard gives you actionable insights on how to improve your supply chain operations. You can closely monitor your fulfilment performance and pinpoint any areas creating bottlenecks in the warehouse. For example, if there are too many orders on hold, you could immediately investigate and look for a possible solution to keep your fulfilment operations running smoothly.

“I can’t say enough about ShipBob’s software and reporting capabilities. It really has made things easy for us to look at the data and make better decisions. Not all partners are set up that way – oftentimes when you’re using other providers’ technology, you have to pull the data yourself, and there’s a lot of work to be done on the back end.

I often brag about ShipBob’s software. We’ve actually shown it off to other software partners to say, ‘We want your system to tell us the things that ShipBob’s software tells us.’ You can tell that ShipBob’s platform was built with the mindset of making their customers’ lives easier.”

Ryan Steffenson, Senior Manager, Channel Operations at Tonies

The analytics dashboard automatically calculates various fulfilment metrics, such as fulfilment costs, average fulfilment cost per order, and average revenue per order. These insights will help you understand whether you’re spending too much on fulfilment so you can look into optimisation opportunities to reduce costs.

For more information on how ShipBob leverages machine learning in our solutions to benefit ecommerce merchants, click the button below to get in touch.

Machine learning in supply chain FAQs

Below are answers to the most commonly asked questions about machine learning in the supply chain.

How is machine learning improving inventory management?

Machine learning is capable of analising huge volumes of historical and real-time data to make accurate predictions about customer demand. This allows businesses to strategically plan their inventory procurement to prevent issues like overstocking and stockouts, so they can maintain optimal inventory levels across their warehouses.

How can small businesses benefit from machine learning?

Small businesses can use machine learning to automate various supply chain processes and improve operational efficiency. They can make informed decisions to restock inventory at the right time and determine the right reorder quantity. This is crucial to avoid overspending on excess inventory and carrying costs while avoiding stockouts.

What tools does ShipBob provide that utilise machine learning?

ShipBob’s inventory management tools come with real-time inventory tracking capabilities and reorder point notifications, so merchants can be instantly alerted when inventory levels dip too low and make timely replenishments.

The platform also analyses historical sales data and combines them with current market trends to help you make accurate demand forecasts. Additionally, the Inventory Placement Program uses machine learning algorithms to determine optimal inventory distribution strategies. That way, you can strategically allocate your inventory to multiple fulfilment centres based on regional demand patterns.